A continuous grounding conductor is a critical component in electrical installations, ensuring that electrical systems remain safe, efficient, and compliant with national standards. By maintaining an uninterrupted path to ground, a continuous grounding conductor provides the necessary protection against electrical faults, surges, and potential hazards. In this detailed guide, we will explore everything you need to know about continuous grounding conductors, including their purpose, installation requirements, benefits, and compliance with codes.

What Is a Continuous Grounding Conductor?

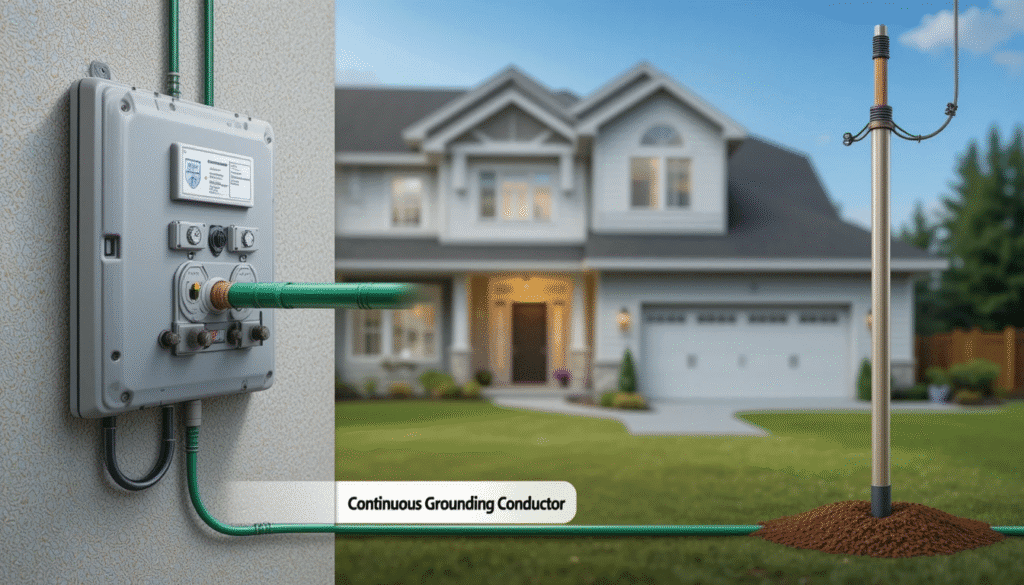

Continuous grounding conductor is an electrical wire, which is usually bare copper or green insulated copper wire. Its main function is to connect the electrical system directly to the ground (earth).

“Continuous” means: this conductor should not be cut or broken anywhere in the middle. Meaning there should not be unnecessary splice or joint in between. This wire provides an uninterrupted path, so that the fault current can easily reach the earth.

Role in safety: It ensures that if there is a short circuit or leakage current in any equipment, then that current gets discharged directly into the earth and does not harm the person or equipment.

Example: Imagine the wire that goes from the main panel of your house to the ground rod installed outside, is the continuous grounding conductor. If it is cut in the middle, the whole house will become unsafe.

Importance of Continuity in Grounding Conductors

The continuity of a continuous grounding conductor is extremely important because:

- Safety: If the wire is continuous, it protects against shock and fire hazards.

- Reliability: Fault current gets an uninterrupted path, which causes the breaker to trip immediately.

- Compliance: Electrical safety codes such as NEC consider continuity to be mandatory.

Real-world example: If an electrician splices a wire in the middle and connects it with just tape and the connection becomes loose, then the equipment (such as a metal washing machine body) may suddenly become live at that time. This increases the possibility of shock.

National Electrical Code (NEC) Requirements

NEC (National Electrical Code) regulates the grounding system. According to it:

- The grounding conductor must always be continuous.

- If splicing is very important, only approved methods such as split bolts, irreversible compression connectors, mechanical lugs can be used.

- The minimum size of the conductor is determined by the rating of the panel and breaker (e.g. copper vs. aluminum have different rules).

- During the inspection, the inspector carefully checks continuity and connections.

Types of Continuous Grounding Conductors

There are two main types of continuous conductors in a grounding system:

Grounding Electrode Conductor (GEC)

- It runs from the main panel to the grounding electrode (such as a ground rod, water pipe, or building steel).

- Its job is to connect the entire electrical system to earth (earth potential).

Equipment Grounding Conductor (EGC)

- It connects every appliance, outlet, and device to the system ground.

- Its job is to quickly conduct any fault current back to the panel.

Materials: Commonly bare copper, green insulated copper, or in some cases aluminum conductors are used.

Methods of Maintaining Continuity

- Using a single unbroken wire (best practice).

- If splicing is necessary, use split bolts or compression fittings.

- Using grounding busbars in large commercial systems.

- Bonding jumpers to connect metallic enclosures.

Best Practices for Installing Continuous Grounding Conductors

- Always choose the shortest and straightest path.

- Choose the correct size conductor.

- Avoid sharp bends or kinks in the wire.

- Label grounding wires to facilitate inspection.

- Keep grounding conductors separate from hot and neutral wires.

Common Mistakes to Avoid

- Splicing with electrical tape.

- Cutting wire into small pieces and joining them.

- Direct joining of copper and aluminum conductors (dangerous because of galvanic corrosion).

- Forgetting to bond metal boxes or panels.

What Is the Difference Between EGC and GEC?

| Feature | EGC (Equipment Grounding Conductor) | GEC (Grounding Electrode Conductor) |

|---|---|---|

| Function | Keeping equipment safe | Connecting the entire system to earth |

| Path | Equipment → Panel | Panel → Ground Rod/Electrode |

| Protection | Protection from shock and fire | Stabilizing the system |

Does a Ground Wire Need to Be Continuous?

Yes ✅ Ground wire must be continuous.

- If splicing is to be done, use only approved connectors.

- NEC enforces this continuity so that the system remains safe at all times.

What Is the Purpose of EGC?

- Provide a low-resistance path for fault current.

- Trip the circuit breaker quickly.

- Protect appliances and users from shock.

What Is a Grounding Conductor?

Grounding conductor is the wire that connects the electrical system to the earth. There are two types:

- GEC: System to electrode.

- EGC: Equipment to system.

Example: The green or bare copper wire connected to an outlet is the grounding conductor.

Applications of Continuous Grounding Conductors

- Residential homes: Main panel, outlets and kitchen appliances.

- Commercial buildings: Large panels, grounding busbars.

- Industrial plants: Heavy machinery, metallic enclosures.

- Renewable energy systems: Solar panels and wind turbines.

Benefits of a Proper Continuous Grounding Conductor

- Protection from electric shock.

- Protection from electrical fires.

- Protection of devices and appliances from damage.

- Increasing system reliability.

- Easier to pass inspection.

Testing and Verification of Grounding Systems

Methods: Continuity testers, clamp meters, insulation resistance tests.

- Regular testing is required to detect corrosion or loose connections.

- Inspectors use special tools to verify continuity.

Future Trends in Grounding Systems

- IoT based smart grounding monitors.

- Advanced corrosion-resistant conductors.

- Integration with renewable energy systems.

- New code updates taking into account safety automation.

Conclusion

Continuous grounding conductor is the backbone of any electrical system. Its continuity is extremely important for safety, reliability and compliance.

Remember – “A proper continuous grounding conductor can be the difference between life and death.”

Always follow NEC guidelines and get the installation done only by licensed electricians.